Эксплуатация и ремонт машин и оборудования

389

degradation is due to the reduction in the useful capacity of the bucket and by partial discharge due

to growth in both the grag when cutting (digging) a result of sticking of wet soil to the working

body and the resistance of the input in the bucket, as well as increasing machine downtime due to

the need cleaning of working bodies are four groups of methods to eliminate adhesionsoil to the sur-

face of the working bodies of earth-moving machinery: methods of creating on the border of the

contract interlayer methods, combined methods in principle action methods and tools to deal with

the nature and the adhesion and frost soil to working bodies of earth-moving machines can be di-

vided into prevention (prevention of adhesion and cleaning bucket recovery evacuates soil capacity)

was found to be most effective combined methods such as combining the dignity of two or move

methods and vibroheated[1-7] the use of high-impact considered in the article relating to the high-

frequency combined methods(a combination of vibration and heating).

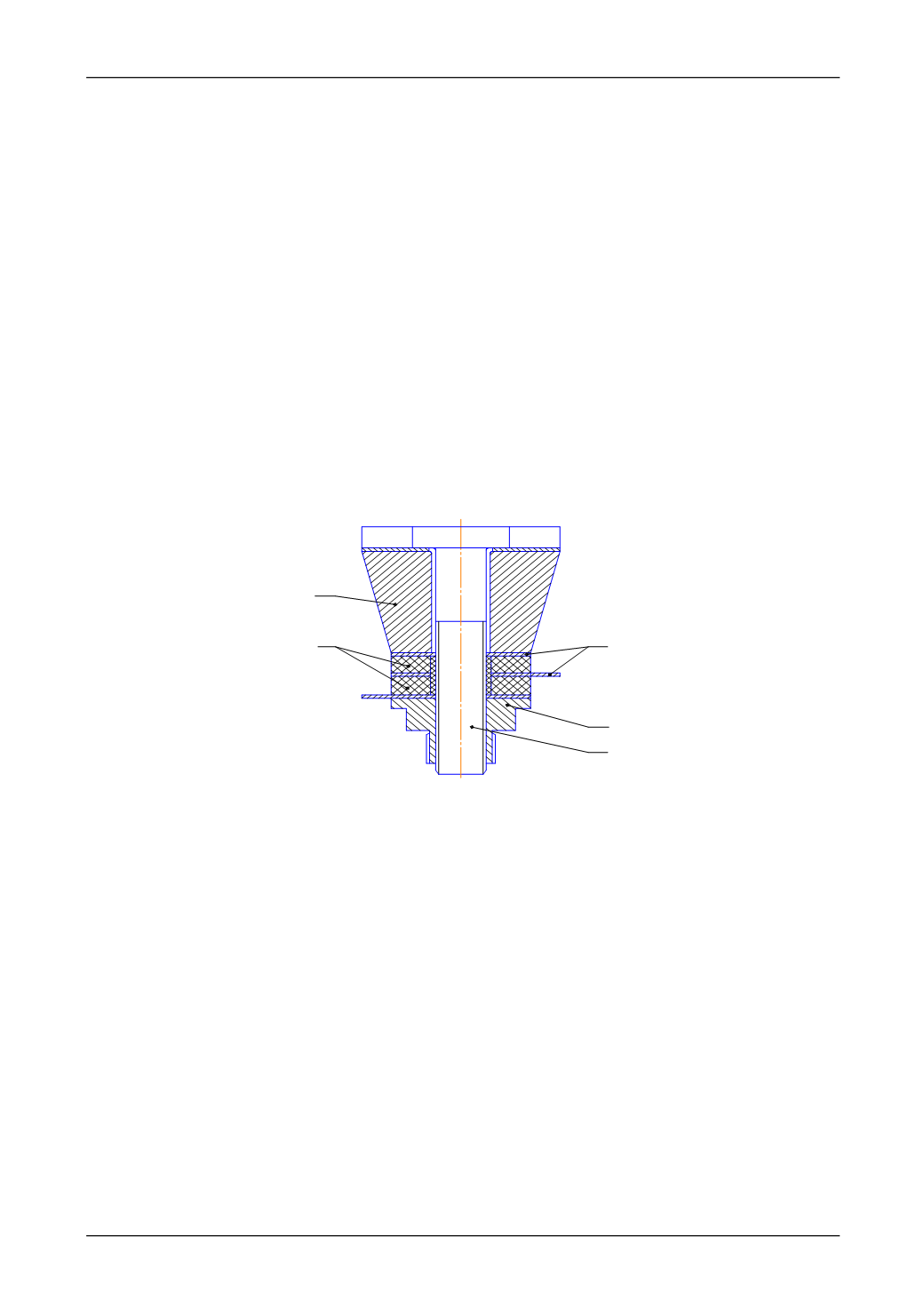

High frequency inverter impact piezoceramic emitters (Fig.1), which consists of 2 ceramic

plates1, top of duralumin D16T, 4 of the bottom lining hundred spacers 3, 0,2-0,3 mm thick mild

foil. Central goes into the holes in the piezoceramic plates and cover plates. The piezoceramic ele-

ments are used to ring mass of PZT-19 with dimensions: an outer diameter of 50 mm, internal 20

mm [8-13].

The experiments were made on a laboratory stand at different environment temperature (-

10

0

C, -15

0

C, -20

0

C). To carry out the tests they take dispersed, connected, the loamy soil of differ-

ent soil moisture content X

1

(W=7,5%; 12,5%; 17,5%).

1

2

3

4

5

Fig.1. Packet structure of converter central bolt 37 kHz.

Essence of the experiment is as follows compactor sample specific weight moisture was

placed on the simulator excavator bucket set in piezoceramic emitters and it was frozen at a certain

temperature for a period of time, after this time the transmitter switched on and the axis of the after

which the sample is fieдd on the compactor simulator [14-16].

The results of processing experimental test series have shown that the required number of

repeated experiments with isolation from the metal surfaces of all types involved in a pilot study of

soil is at least three regression equations of fig. 2, 3 shows a graphical interpretation of the follow-

ing mathematical treatment of the experimental results using AdvancedGrapher program.

In this graph it can be concluded that the soil sample for separation by freezing termination

period of 15 minutes, the surface excavator simulator with 7,5% weight moisture, regardless of the

ambient temperature requires the longest time exposure converter since in the ground water and a

small amount of sample is not only freezes to the metal adhesion occurs and therefore the need for

greater amounts of energy drying the soil in contact with the metal. For soil moisture with a weight

of 17,5% is to be a little less exposure time converter since in wetter soil strength soil freezing to

the metal is caused by the strength of the ice, and is known under the thermoacoustic effect on the

frozen ground in the first place is the destruction of ice contained in the soil. The graph also shows

that soil moisture with weight 12,5% must be the least enough for lasting freezing do the metal, but

do not already occurring soil adhesion process, because water freezes faster.