Механики XXI веку. № 15 2016 г.

436

and soil-working component surfaces adhesion is observed. The main approaches to the study are: 1) to establish the

parametres of the frictional stress

on the soil-metal surfaces interaction taking into acount the adhesion phenomenon

under freezing, the preventive effect as well as; 2) to evaluate, experimentally, the effects of external factors (the press-

ing pressure, environment temperature), determine the soils adhesion at negative temperatures, the strength of the soil

freezing and the metal surface of the working unit; 3) to make the pilot studies to clear the mechanisms that determine

the soil moisture action, the contact time, the environment temperature on the metal surface of the working body when

the boundary intermediate layer is formed; 4) to fix dependences defining the preventive machines action parametres

responsible for the soil-metal surfaces freezing strength. This paper presents the experiment’s results concerning the

application of anti-icing fluid as a preventive element to create when the boundary intermediate layer is formed. Ob-

tained regression dependences of the function response to the shift tension both from several factors and quasi single-

factors.

The cause difficulty of machines units - moisture soils/materials is the adhesion which increases

when digging, unloading, hauling and leveling operations[1-3].The adhesion decreases productivity sharply

(by two times) and power consumption increases. The applied methods to minimize the adhesion can be

divided into four groups [4-11]. For example, to create the screen layers applying anti-icing liquids (AIL).

Let’s consider the application of AIL "MAXFLIGHT 04" which is the anti-icing liquid based on propylene

glycol [12].

Pilot studies of soil - metal surfaces shift tension using AIL "MAXFLIGHT 04" were conducted (at

the environment temperatures:-35,-15 and +5 ºС). The experiments were made on the shift stand [13, 14]

using the principle of the mathematical theory for experiment planning [15, 16].

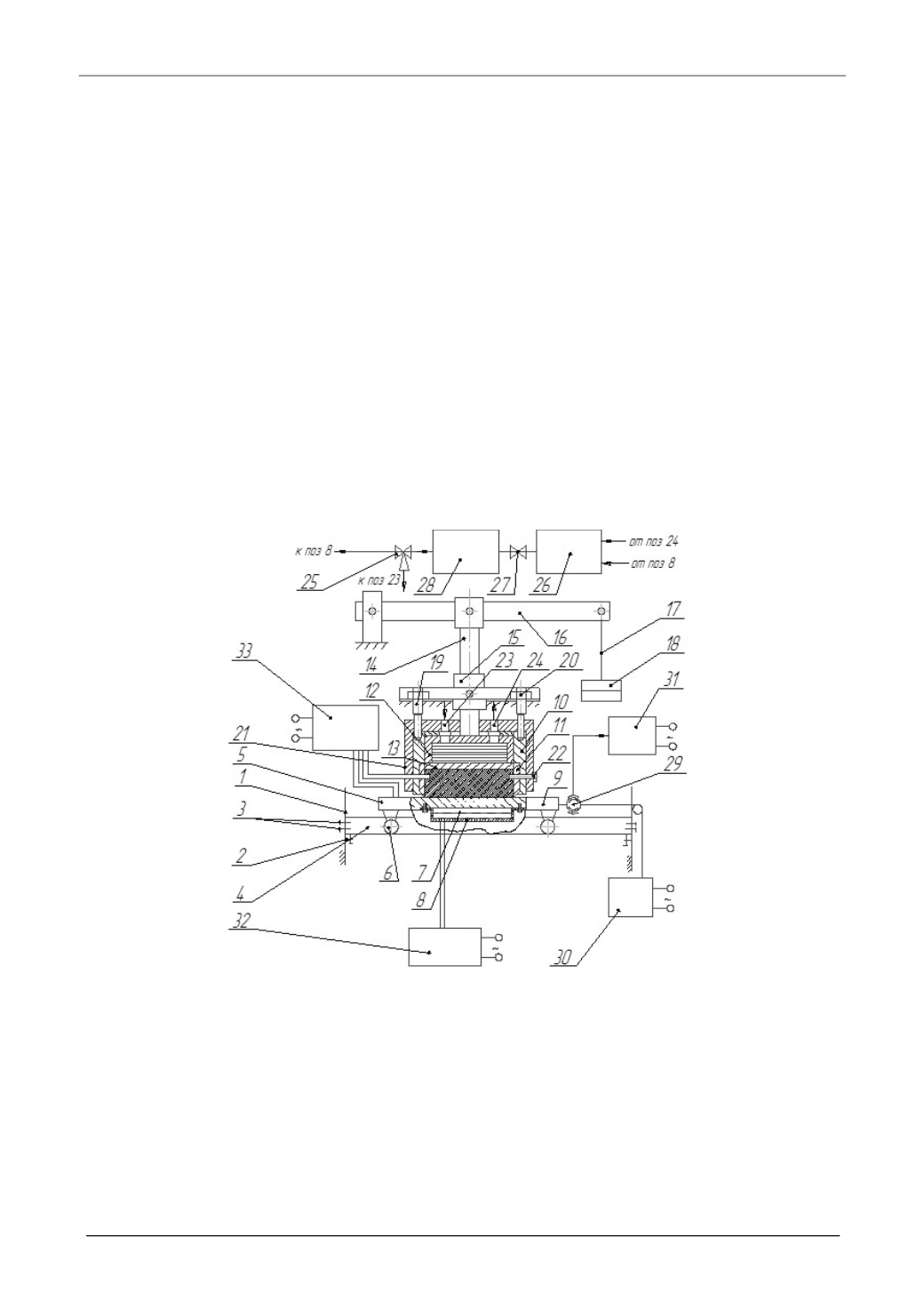

The schematic diagram of the shift stand is shown on Fig. 1

Fig. 1. The schematic diagram of the experimental shift stand to test the liquid intermediate layer effect on the soil

freezing strength

The stand (fig. 1) consists of the frame 1 with screws 2, the bolted joints 3 guides 4, the carriage 5

provided with rollers 6 and installed movably in guides 4, rigidly fixed on the carriage, the AIL tanks 7 (pro-

vided with AIL feeding system 32), with the heat isolated case 8 and a metal shift surface 9, a cylindrical

holder 10 without bottom, a removable ring 11, a stamp 12 and cap 13. The stamp 12 by the threaded cou-

pling is connected with the bar 14 which can move vertically in a guide bush 15 and is hinged to the load

lever 16 one end of which on was the support is 17 where replaceable loads 18 are located. The holder 10

held by studs 19 and nuts 20 is attached to a metal structure 1, and can be regulated and is provided with a

heat-insulating housing 21. The removable ring 11 is fixed in it by two bolts 22. The removable ring 11 is

made of shock-resistant high pressure polyethylene. The inner diameter of the ring 11 is equal to the external