Современные технологии и автоматизация в машиностроении

195

properties of the processed materials. When rigorously present particles bounds inside material break be-

cause the processed workpieces are separated into components with chippings. Basic characteristics of the

cutting process depend on a number of the following factors [5]:

1) the banks specifications: the sort of material, its physical and mechanical properties, the binder

elements, etc.;

2) the tool specifications: angular parameters, physical and mechanical properties of the cutter mate-

rial, the degree of the surface roughness, edge sharpness, and so on;

3) the processing modes and dimensions: thickness and width of the layer, the feed and cutting,

speed thickness machining allowance, the cutting direction with respect to the preset direction of fibers, and

so on.

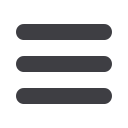

Table 1

The applied methods of composite materials processing

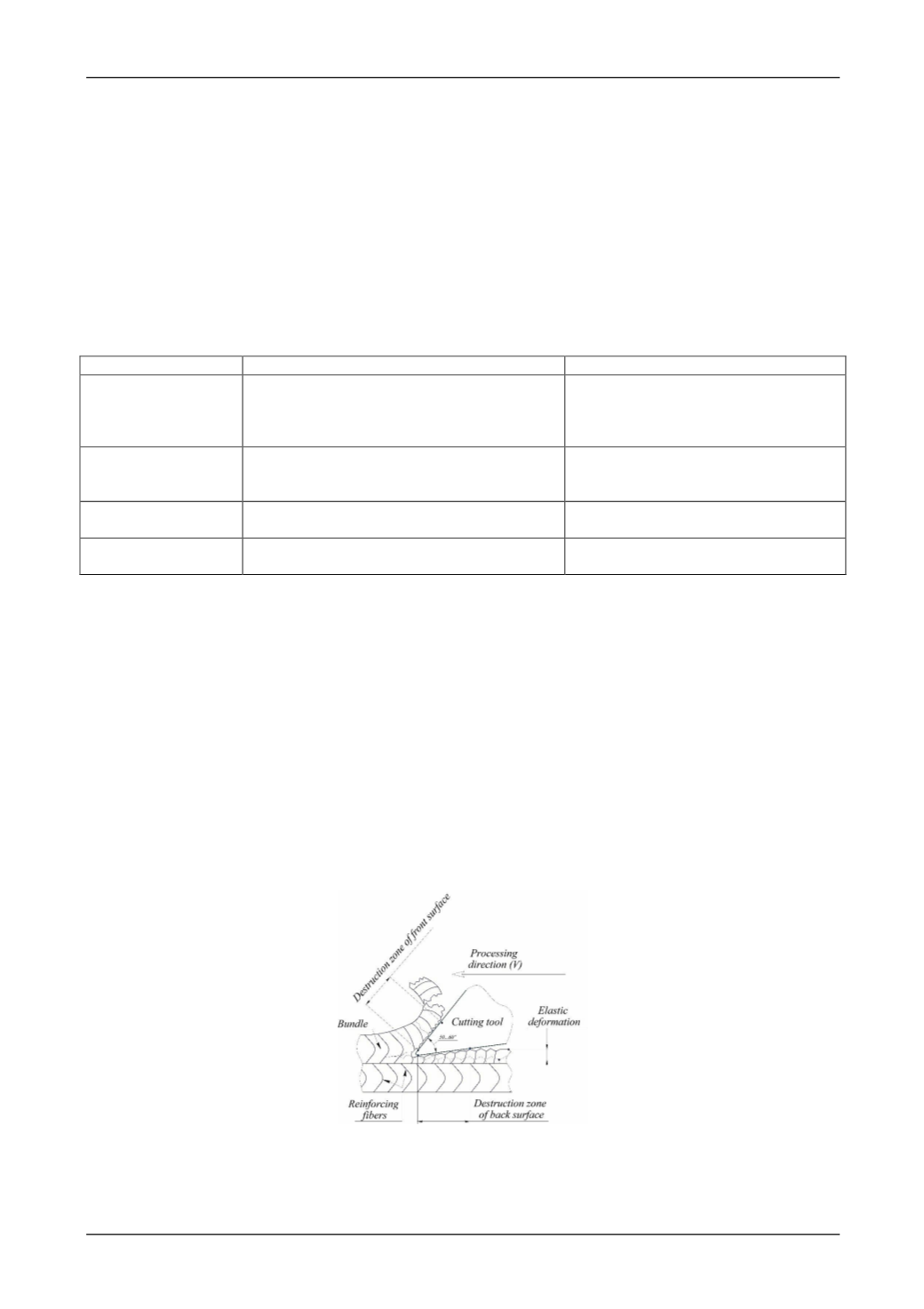

Analysis of the work of the authors [7 – 10] revealed some features of the composite materials cut-

ting. As a rule, during the composites processing wear phenomenon occurs on the back surface of the tool

due to the elastic material recovery after the cutting wedge remove (Fig.1). The tool front surface wear is

slight and results from abrasive wear of the workpiece material, and the chip friction on the front surface and

significant heat in the cutting zone. The comfortable condition for composites cutting is when the tool edge

is sharp enough to prevent any the tool- workpiece friction. The tool wear should also be minimized, since

any change of the cutting blade geometry result in an instant temperature jump in the cutting zone and

influences on its critical wear. The geometry of the tool should be selected to provide efficient process apply-

ing the minimal cutting force [6 – 12].

Recommended geometrical parameters of the cutting tool intended for composites processing are

specified by the following range of requirements: front corner: γ = 20... 30°, clearance angle α = 10...15°,

sharpening angle β = 50...60° [8, 13].

The above given parameters are designed taking into account the conditions and requirements for the

technological processing of the manufactured articles. They define the cutting process and cutting force de-

gree, chip forming process, and the surface quality obtained after machining [5].

Fig.1. Wear mechanism of cutter surfaces when composite materials processing.

The processing features of the composite materials show that under continuous development of de-

tails manufacturing technology of composites, and there is the need in developing specialized tools taking

Тype of processing

Advantages

Disadvantages

Mechanical

Low roughness degree, high of machined

surface accuracy

High tool wear and its effect on the

processing quality, separation, tearing

fibers, the likelihood of thermal

degradation of the matrix

Jet - abrasive

Deficiency of thermal degradation of the matrix,

the large thickness processing, high level

performance

High surface roughness, the danger of

swelling in water

Laser

Small cut’s width, high speed cutting,

processing fragile detail

Thermal the destruction of the matrix,

smoke and dust formation

Ultrasonic

High machining accuracy, low surface

roughness, minimal material separation

Low productivity, tool wear